Industry Leading Precision Bearing Repair.

Save 50% Or More On Your Bearing Spend!

Bearing Repair: Recertify

The bearing recertification service is one of four types of bearing repair that BSC offers our customers. Each method provides unique advantages, which is why we invite you to explore our bearing recertification process further and determine if this service is the right one for you!

Recertify for Cost-Effective Bearing Repair

When choosing between the different types of bearing repair services it is important to consider factors, such as cost. In comparison to the other methods of bearing repair, our bearing recertification service is by far the most cost-effective option available. By recertifying your bearings, you are estimated to save up to 90% compared to the cost of completely new bearing components. While every repair service can be expected to provide considerable cost savings as opposed to new bearing investments, recertifying bearings offers the highest percentage of potential savings of all repair options.

Quick Turnaround for Bearing Recertifications

In addition to being the most cost-effective bearing repair option, recertify services are time-effective. With an average estimated lead time of 1-2 weeks, bearing recertification can accommodate even the tightest production schedules. If downtime poses a significant risk to your business, contact the BSC bearing recertifying team today!

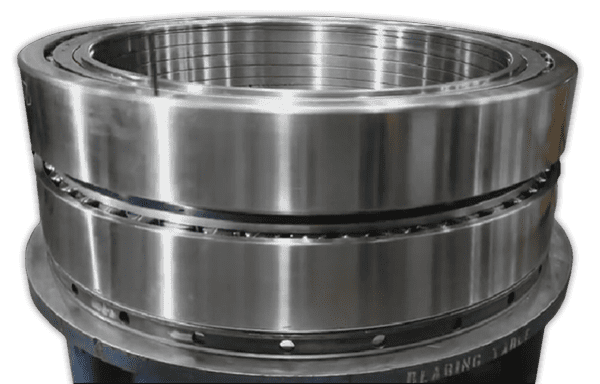

The Bearing Recertifying Process

Disassembly and Cleaning

During almost all types of bearing repair projects, the bearing will be carefully disassembled and thoroughly cleaned. Every critical dimension will be measured and compared to manufacturers’ specification to determine which repair service is necessary. Damage modes will be identified to help determine the root cause of any fatigue present. The only repair service we offer that does not involve disassembly and cleaning is bearing modification.

Measurements and Inspection

Full inspection reports are provided to the customer as part of the bearing recertification process. These reports include beneficial information, such as serial numbers, damage modes, incoming critical dimensions, and manufacturer’s specification dimensions.

Polishing and Assembly

Once all the components have passed dimensional and magnetic particle inspection, they are assembled and checked for running clearances. In addition to general assembly services, our bearing recertification process also includes polishing to ensure that the final result is up to our customers’ industry standards.

Preservation and Packaging

Once bearing recertifying services are complete, each bearing is coated in rust-preventing preservative, wrapped, and packaged or crated for protection. Each label will indicate the bearing OEM, part number, and serial number.

Quality Control for Bearing Recertify Services

BSC has an uncompromising dedication to quality control, coupled with modern equipment, top-grade materials, performance-tested products, and the work of our highly skilled technicians. Our steel is locally sourced and all of BSC products are manufactured at our 88,000+ sq. ft. manufacturing facility in Pittsburgh, PA. Because BSC is confident in the quality of our services, we offer a 12-Month Warranty that can be applied to every bearing recertifying project.