Industry Leading Precision Bearing Repair.

Save 50% Or More On Your Bearing Spend!

Bearing Repair: Remanufacture

Bearing remanufacturing is the most involved bearing repair service that BSC offers. While bearing recertification and reclamation typically bring isolated parts of a bearing component back to industry standards, bearing remanufacturing will be the closest option to producing a brand new bearing. Because of this, bearing remanufacturing services come with the longest lead times, generally estimated at 10-16 weeks. Despite a slightly longer wait time, bearing remanufacturing is highly effective, providing customers with like-new parts while still saving them up to 50% compared to cost of new bearings.

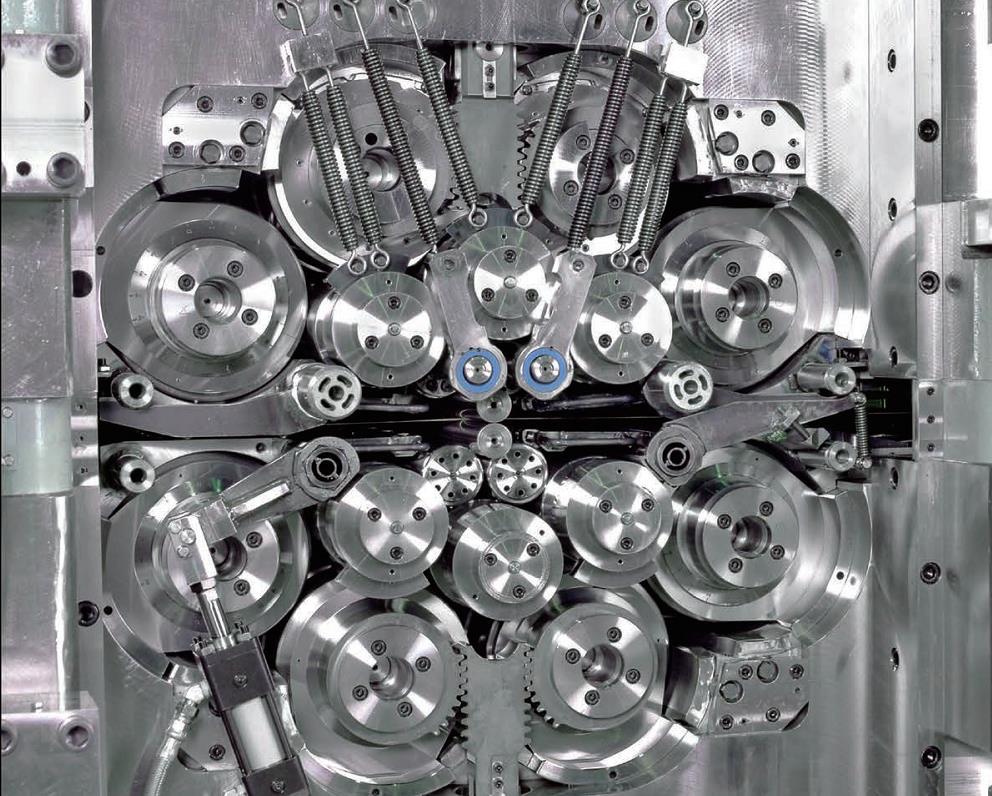

The Bearing Remanufacturing Process

Disassembly and Cleaning

The bearing remanufacturing process requires that all parts being repaired must be disassembled and cleaned. This allows our repair team to fully understand where any performance issues lie so that we can best remedy them during the bearing remanufacturing process.

Measurements and Inspection

In addition to disassembly and cleaning, specific repair strategies will be determined during the measurements and inspections stages of bearing remanufacturing. Each customer receives a full inspection report for their bearing remanufacturing project.

Vibratory Polishing

While bearing recertifying services involve a generic form of polishing, both methods of bearing remanufacturing and bearing reclamation use vibratory polishing for the repair process. This option is popular among customers due to its ability to save time and lower repair costs.

Regrind or Replace Raceways

Machining raceways works to remove stressed or fatigued material from the bearing being remanufactured. By removing surface damage and maintaining raceway profiles, the raceway regrinding and replacement processes improve bearings and provide fresh rolling surfaces that optimize component efficiency.

Manufacture and Install New Rollers

The bearing remanufacturing process often involves manufacturing and installing entirely new rollers. Larger rollers are manufactured to be used as a way to maintain predetermined clearances after the raceway machining process. All of our rolling elements have a prescribed crown and radii for optimal performance.

Bearing Assembly

Once raceways have been machined and new rollers have been fully installed, the BSC team completes the bearing reassembly process. This step of the bearing remanufacturing process involves replacing the bearing cage and verifying that all dimensions and specifications have been restored to our customers’ standards.

Preservation and Packaging

The final stage of the bearing remanufacturing process involves coating each bearing with a rust-preventing preservative that will extend the product life of our customers’ bearing components. After BSC packages and ships these remanufactured bearings back to our customers, our customers have access to a 12-month warranty that can be applied to every bearing repair project.