Grinding.

Your Premier Source For USA Manufactured Bearings.

Grinding

After receipt of parts from heat treat, the parts are identified, inspected, and then ground to precision size. Explore how BSC uses our grinding services to serve our customers’ needs:

The Grinding Process

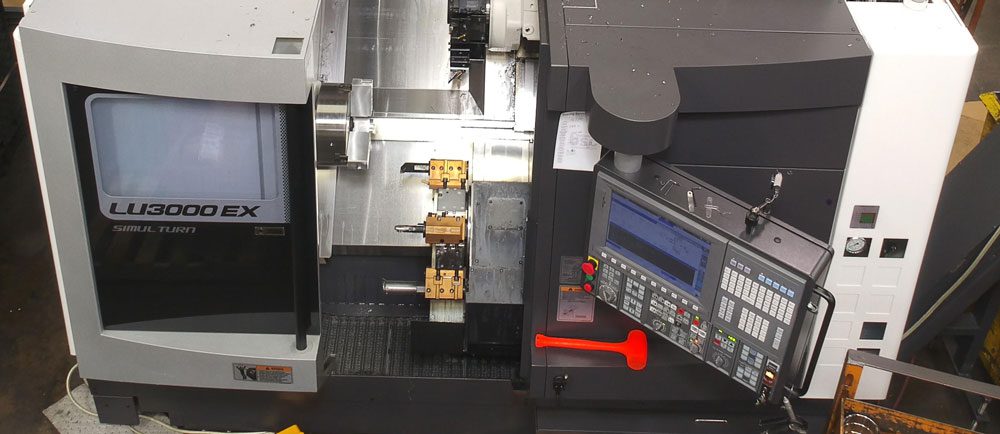

Generally grinding takes place in three different phases, namely surface grinding, bore grinding, and OD grinding. BSC has conventional bore and OD grinders, vertical grinders, and CNC grinders to complete each step of the grinding process. All processes are recorded, inspected, and documented as per the process sheet.

Regrinding Services

BSC has the ability to re-grind used components through our remanufacturing process. This provides the rollers with a new surface finish to OEM specifications. When reusing good components during the repair process, we can greatly extend the life of the bearing while maintaining cost efficiency. Depending on the complexity of the parts, they may require special grinding equipment and fixturing.

Uncompromised Grinding Service Quality

Our company is proud to be ISO 9001 certified, allowing us to meet global standards for quality manufacturing. We have implemented process controls, in-process inspections, extensive software to track gage calibration, and tracking of material and heat-treat certifications. We also have a coordinate measuring machine (measuring accuracy to 0.00005″) in a temperature-controlled room, for all in-process and final inspections of dimensions, roundness, concentricity, and taper. All material certificates are filed in accordance with ISO requirements for future tracking and cross-referencing.

Our company is proud to be ISO 9001 certified, allowing us to meet global standards for quality manufacturing. We have implemented process controls, in-process inspections, extensive software to track gage calibration, and tracking of material and heat-treat certifications. We also have a coordinate measuring machine (measuring accuracy to 0.00005″) in a temperature-controlled room, for all in-process and final inspections of dimensions, roundness, concentricity, and taper. All material certificates are filed in accordance with ISO requirements for future tracking and cross-referencing.

Materials We Can Grind

BSC is not restricted to a certain grade of steel for bearing manufacturing, but instead accommodates the requirements for customers’ applications. This includes special tool steels for high-temperature stability as well as corrosion-resistant bearings. All material certificates are filed in accordance with ISO requirements for future tracking and cross-referencing.

Our Manufacturing Capabilities:

Bearing Types

- Ball Bearings

- Cylindrical Roller Bearings

- Thrust Bearings

- Tension Leveler Units

- Z-Mill Bearings

- Linear Bearings

- Sleeves

- Bearing Components

- Specialty Bearings

- Discontinued Bearings

Size Range

- 2″ ID to 60″ OD

Precision Level

- ABEC 1, ABEC 3, ABEC 5, ABEC 7

- RBEC 1, RBEC 3, RBEC 5, RBEC 7

- P0, P6, P5

Materials

- Through Hardened Steels

- 52100

- 440C Stainless Steel

- M50

- Case Carburizing Steels

- 8620

- 3310

- 9310

- Cage Materials

- Bronze

- Brass

- Steel

- PTFE, Nylon

- Ductile Iron

BSC is not restricted to a certain grade of steel for bearing manufacturing, and instead accommodates the requirements for customers’ applications. This includes special tool steels for high-temperature stability as well as corrosion-resistant bearings.

All material certificates are filed in accordance with ISO requirements for future tracking and cross-referencing.