Service that you can trust.

We help get the job done.

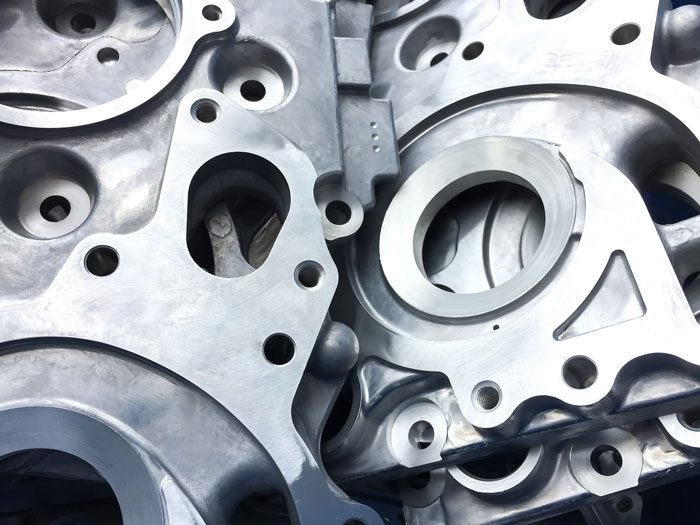

Reverse Engineering

In addition to manufacturing new bearings from customer-provided drawings, BSC also provides our customers with reverse- engineering services for projects where bearing spec drawings cannot be provided.

The benefit of reverse engineering is simply that reverse engineering can be conducted based upon the part itself that the customer sends to our facility. This allows us to make sure every part of the bearing is functioning properly in its design. There have been a number of jobs where, during the reverse-engineering process, the problem with the bearing has been exposed. In some cases, envelope dimensions will still be required for reverse- engineering projects. BSC encourages our customers to send any information that might be relevant to the bearing manufacturing process, but the reverse-engineering process largely takes the burden off of our customers as it concerns design information.

Quoting Reverse-Engineering Projects

No two reverse-engineering projects are the same. BSC can provide rough estimates until our engineering team has enough information regarding the project, which varies with every application. All information sent in from the customer regarding nomenclature and manufacturer will help speed up the quoting process that will allow us to diligently be as competitive as possible.

In the bearing world, we set ourselves apart with our skills in discovering which bearing or design changes our customers need and properly quoting the order. While drawings are always ideal, BSC is proud to offer comprehensive reverse-engineering services.

Reverse Engineering Using Damaged Bearings

Because our customers come to us to repair damaged bearing parts, it is common that the components they send us for reverse engineering are severely damaged. Luckily, our experts are capable of evaluating even the most extremely compromised bearings.

Our team has even worked on a number of projects where the bearing in question is sent in pieces after exploding during use. Even if the bearing is in pieces, as long as we have envelope dimensions, BSC can provide solutions for our customers.

Reverse Engineering for Small-Run Orders

While larger manufacturers don’t like to fulfill reverse-engineering orders for projects involving small runs, BSC eagerly takes on even the smaller opportunities to make job shop-type products. We have built our business around customer needs, meaning we do not limit ourselves to merely fulfilling orders based on size. If you are interested in working with a company that puts your business first, look no further.